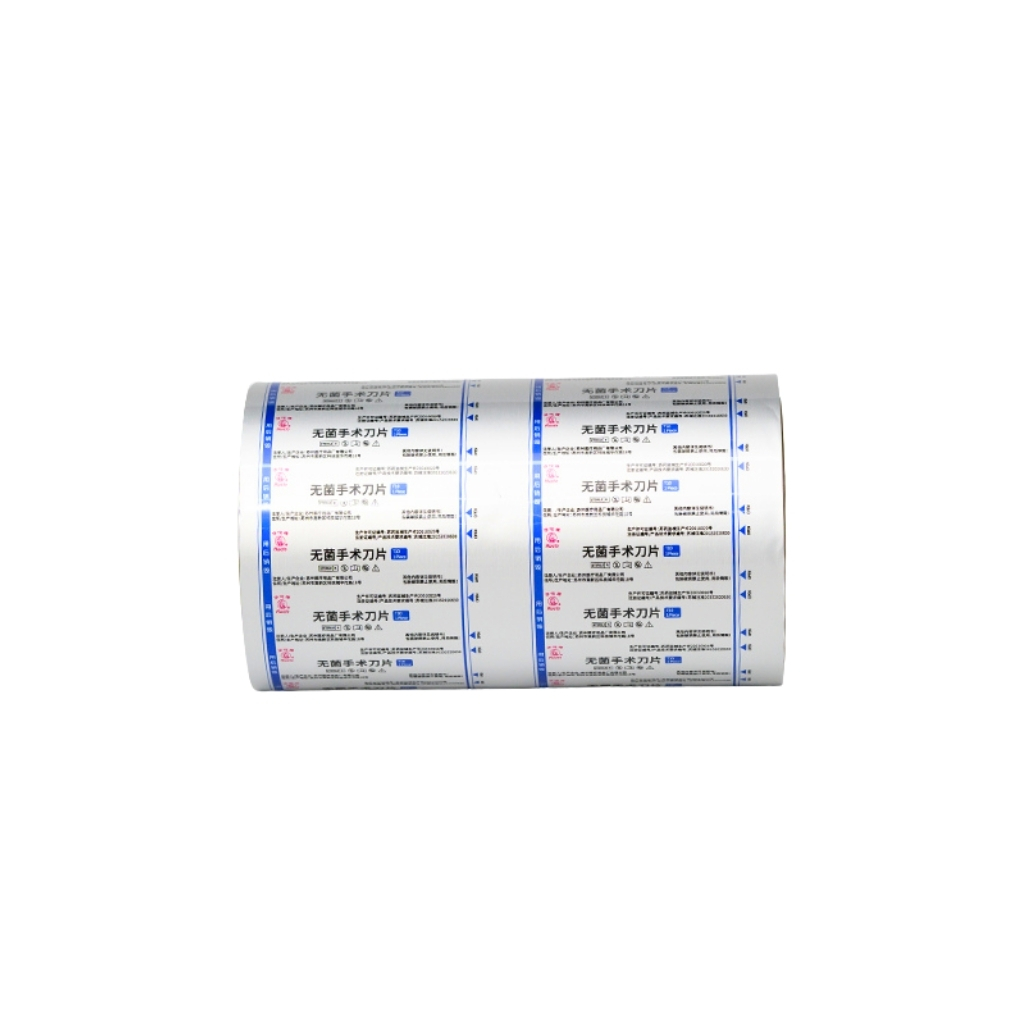

Description

Features

- Printed aluminum foil with protective coating

- Heat-sealable with PVC/PP/NY/AL

- Light-blocking, easy to open

- Designed with an easy-to-push-through or puncture foil layer, ensuring convenient and quick access to tablets

Applications

Suitable for tablets, capsules, pills packaging

Why Choose Us?

- Comprehensive Packaging Solutions

- Safety & Compliance

GMP-certified cleanroom production ensures safe packaging environments for food and pharmaceuticals. - Functional Innovation

Optional NFC anti-counterfeiting tags (ERP-integrated) and temperature-sensitive color-changing labels for real-time cold chain monitoring. - Small-Batch Customization & Fast Delivery

Equipped with HP digital printing machine to support small orders and rapid delivery. - Sustainability Value

Mono-material solutions designed for enhanced recyclability.